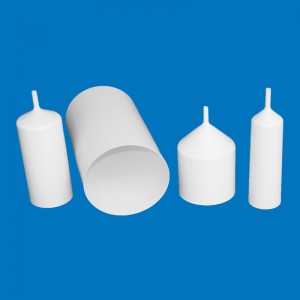

Titanium crucibles

The melting point of titanium is high.

The boiling point and the melting point of titanium is also high.

Titanium has good heat resistance, and it is used in the discs and blades of aero engine compressors and the skin of the rear fuselage of aircraft.

Titanium is not corroded in some corrosive media, such as seawater, wet chlorine, chlorite and hypochlorite solutions, nitric acid, chromic acid, metal chlorides, sulfides and organic acids.

Titanium alloy has good heat resistance, low temperature toughness and fracture toughness, so it is mostly used as structural materials for military supersonic aircraft, compression parts of jet engines, components of aircraft frames, casings, fire walls, rivets, structural parts of air equipment and structural parts of rockets and missiles.

The amount of titanium used in civil aircraft accounts for about 20~25% of the weight of the frame, and the aircraft made of titanium alloy carries more than 100 passengers than the aircraft made of other metals with the same weight.

The strength of some titanium alloys (such as Ti-5AI-2.5SnELI) increases with the decrease of temperature, but the plasticity does not decrease much, and it still has good ductility and toughness at low temperatures, which is suitable for use at ultra-low temperatures. It can be used in liquid hydrogen and liquid oxygen rocket engines, spacecraft, artificial satellite antennas, ultra-low temperature containers and tanks on manned spacecraft, etc.